At Your Service

Wherever You Are, We’ll Get You Sorted. Fast.

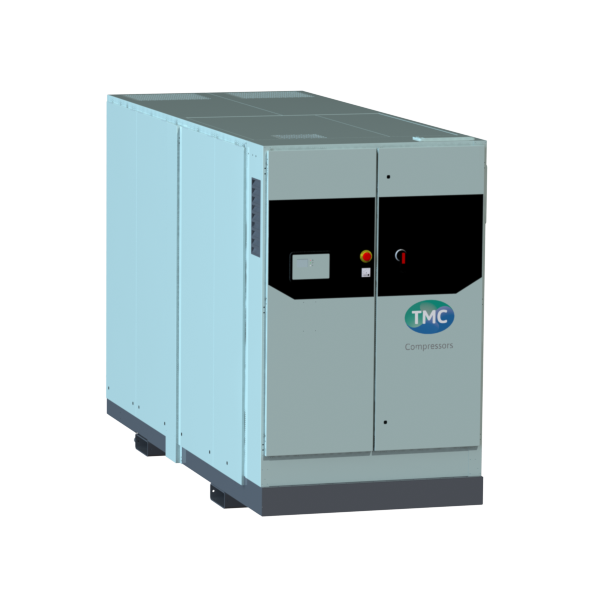

Continuous, safe and reliable operation are our guiding principles. Therefore, TMC's marine and offshore compressed air systems are designed to enable your vessels crew in conducting planned maintenance and service by themselves.

However, the need for professional service and support is sometimes paramount, as compressor installations become more complex and critical for operations. TMC`s service support is available 24/7.

Dedicated team

We have a dedicated team of service engineers with all necessary authorisations and certificates, ready to travel the globe on short notice from different locations. Our service phone is manned by a service engineer 24/7. You can also contact us via e-mail or on-site.

Our service team can be reached 24/7 by calling +47 992 17 020.

They are familiar with the demanding conditions onboard your ship or offshore installation. Depending on the complexity of the issue, we can either help you remotely or jump on the next plane to assist your crew on board your vessel.

Tips and Tricks

-

Importance of Correct working temperature

Incorrect working temperature may lead to unwanted downtime.

If the working temperature is too low compared with the ambient temperature, condensing water will accumulate with the oil. This is due to physical properties, where main factors are temperature, pressure and humidity.

In order to avoid accumulation of water in the oil, the working temperature should be 50-55 ° above the ambient temperature. All our compressors from 35Kw and bigger are equipped with the patented TMC Thermal Mixing Valve (TMV) that automatically adjusts the compressors running temperature according to the actual ambient conditions. -

Mixing of Oil

Mixing of Oil may cause oxidation in the Oil. When changing from one brand to another, it is essential that system is flushed with the new oil. This is because some oil will be trapped inside the system and not drained out completely.

Fill up with the new brand. Run the system until normal running temperature are achieved (20-30 minutes). Then drain the oil and fill up again. At the same time, change the Oil filter. -

Replacing beltsWhen replacing belts, it is essential that the whole set is replaced at the same time, as belts will expand after the first running hours. The belts must come from the same production batch, to avoid deviations in length.

Whenever replacing belts measure and check the wear of the pulleys at the same time. If the pulleys are worn the new belt lifetime will be drastically reduced.